Capacity: 50-1000 t/h

Maximum Feed Size: 0-250 mm

Tire Types: Flat Belt, Banded Belt, Sergeant Belt

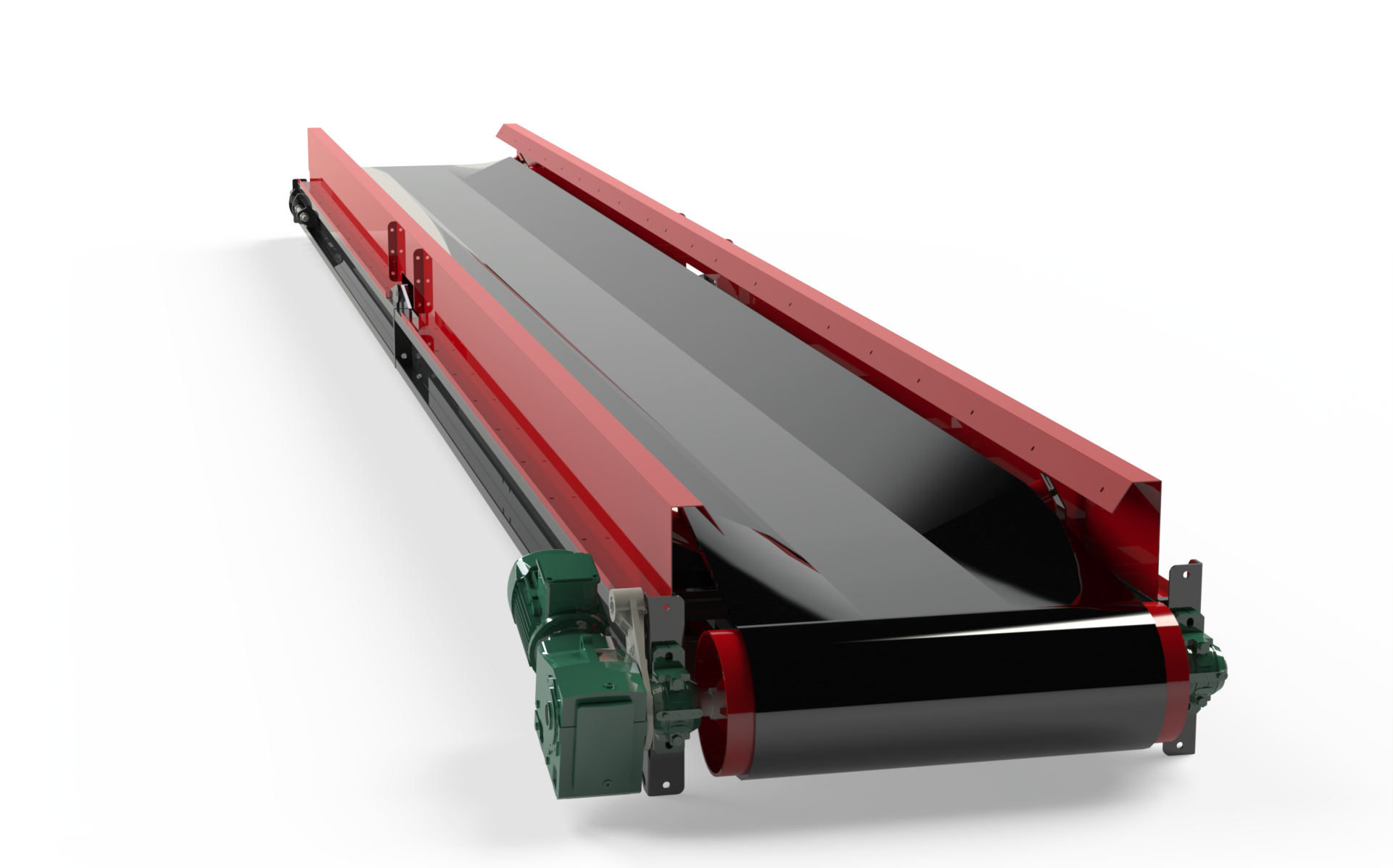

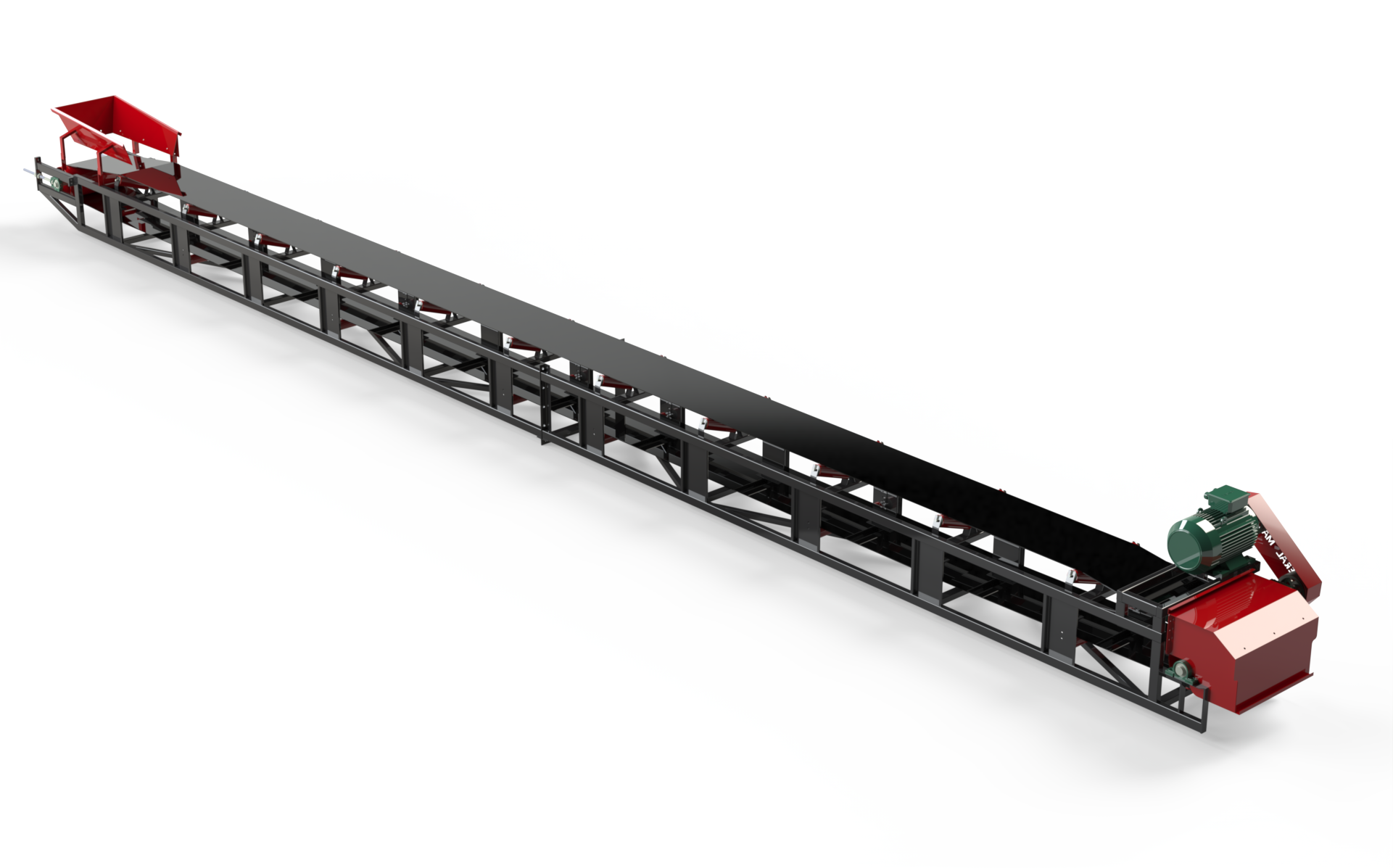

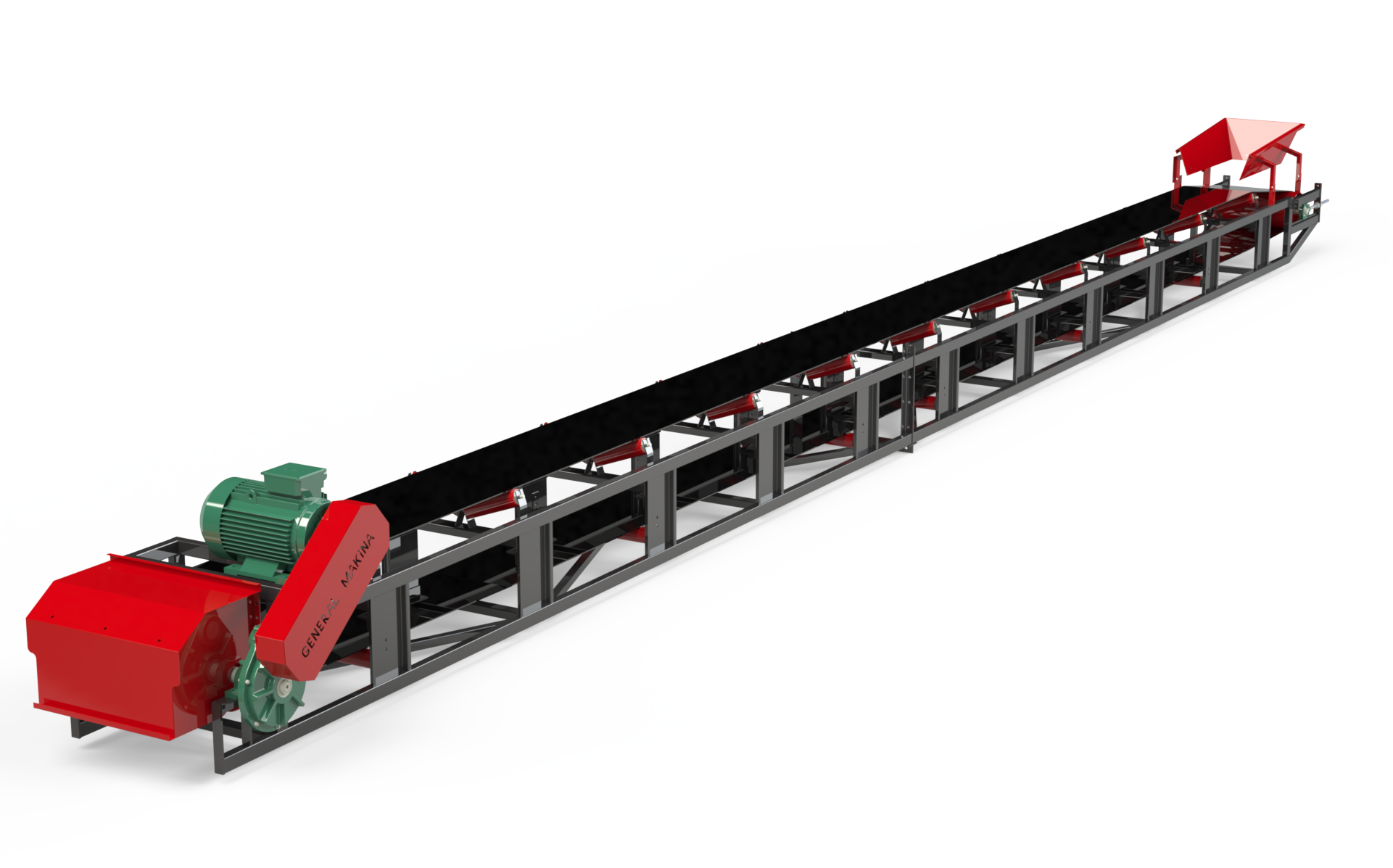

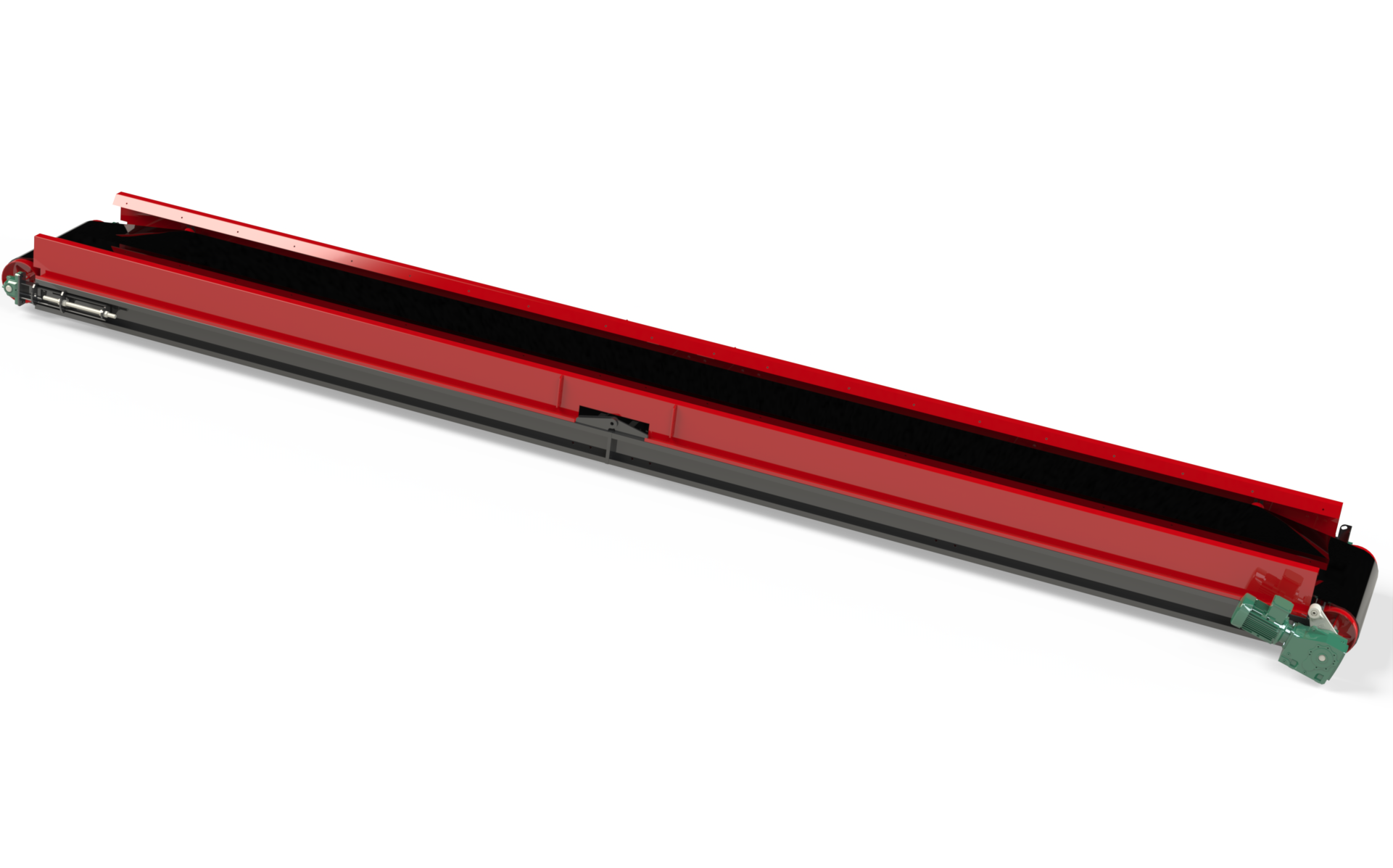

General Machinery manufactures conveyor belts from the box profile, cage or sheet chassis. Our conveyor belt with outstanding quality and reliability, it is produced of 500, 600, 700, 800, 900, 1000 and 1200 mm in 7 different widths and desired length. General Machinery product conveyor belt usually is used "Shaft-mounted" reducers and is positioned different chassis with the electric motor on the "V-belts" are driven.

Conveyor Belt Technical Specifications:

- Robust carrier frame

- Quality rubber band

- Quality rolls

- rubber covered rolls in shock loading

- The drive and tail drums with SNH type bed

- Front and behind scraper tires

- Bolts merged Chassis

- Standard chassis modules when needed to change the band size

- Pin connection carrier feet

- Custom manufacturing seals slide tensioner bearings

- Tapered bushing pulleys for ease of assembly and disassembly.

Technical Specifications for Conveyor Belt Components:

1. Drums

Drums will have conical hub connections to the shaft.

The drive drum will be rubber-vulcanized.

2. Rollers

The carrier roller will be mounted at a maximum distance of 1 meter, and the return roller at 3-meter intervals.

The carrier and return rollers are ø 76mm in diameter and pipe-bearing welded.

The impact rollers at the loading point are rubber-coated.

3. Belt Rubber

The belt rubber will be original cord fabric, Kale brand.

The splice will be of infinite length, hot-vulcanized, and made of EP polyurethane cord fabric.

Rubber strength will be standard EP 100 – 4 ply.

EP 125 – 4 ply belt rubber will be used under the impact crusher.

4. Conveyor Frame

The frames are manufactured with a specially bent, carcass structure, with a sheet metal thickness of 4 mm for 600-900 conveyors and 5 mm for 1000-1200 conveyors.

5. Drive Unit

Unless otherwise specified, General Makina will select a motor from Gamak, Emtaş, Abana, or İnter.

The gearboxes are from Polat and Ege brands.

The drive is motor-gear belt-pulley connected, with the gearbox coupled to the shaft.

In necessary cases, gearboxes are used with a reverse lock.

OPTIONAL FEATURES

PLS-controlled automatic lubrication system

Cable switch and tachometer

TR

TR EN

EN RU

RU FR

FR ES

ES AR

AR SR

SR